As a result, he entered another period of disappointment and embitterment, As a result, he entered another period of disappointment and embitterment,

during which hated the world for its ignorance of the efforts and achievements

during which hated the world for its ignorance of the efforts and achievements

he had made. Eventually, he got through his depression and began to think

he had made. Eventually, he got through his depression and began to think

about the word, ‘tradition.’ He decided to start again, but this time tried to establish

about the word, ‘tradition.’ He decided to start again, but this time tried to establish

what his grandfather and father had stood for by using the traditional methods,

what his grandfather and father had stood for by using the traditional methods,

materials and tools they had utilized. He made bowls and dishes of all shapes and

materials and tools they had utilized. He made bowls and dishes of all shapes and

sizes as his seniors might have made them if they had been alive, and entered some of

sizes as his seniors might have made them if they had been alive, and entered some of

his pieces into a folk craft show the following year. The works received the Critic’s Choice

his pieces into a folk craft show the following year. The works received the Critic’s Choice

Award ('Ipseon') and the judges commented that they reminded them of days gone by when

Award ('Ipseon') and the judges commented that they reminded them of days gone by when

life was simpler and people were happier. The panel praised his artworks for the coarse texture

life was simpler and people were happier. The panel praised his artworks for the coarse texture

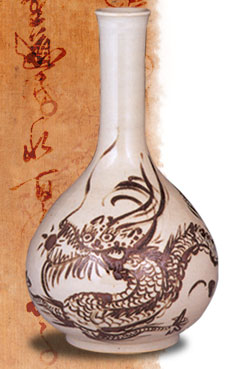

of the sandy clay, the brilliance of the blue glaze, their simple but dynamic designs made by carefree

of the sandy clay, the brilliance of the blue glaze, their simple but dynamic designs made by carefree

brush strokes, as well as their voluminous form. They said his productions were a fine legacy of Joseon maksabal

(‘all-purpose bowl’) that beautifully reflects the simple life of the common people. They were, in short, an incarnation

of the glorious tradition that his family had maintained for approximately two centuries, despite great hardships and

adversity.

His faith and confidence returned at last, Kim concentrated his energy into reviving the

traditional Joseon ceramic ware his ancestors had created, and was awarded the

National Folk Craft Show‘s Special Prize in both 1988 and 1989. In 1991, he received

the honorary title of Myeongjang (‘Master Artist’), becoming the first potter to have been

bequeathed such a tribute. But the highest honor came in 1996 when he was

designated by the Korean government as Sagijang (‘Master Potter) of an ‘Important

Intangible Cultural Property,’ which corresponds to the UNESCO term, a ‘Living Human

Treasure.’

Even though titles and accolades have been bestowed on him, his life as a potter has

not changed at all. Like his ancestors, he begins and ends each day creating wonderful

masterpieces using age-old techniques and traditions that have been lovingly handed

down from father to son for many generations.

Kim Jeong-ok, who is also known by his penname, Baeksan (‘White Mountain’), is an

artist who knows how to make a ceramic bowl as affable and gracious as the earth

from which it is born. The Joseon white ceramics’ modesty and unpretentiousness

is one of its most beautiful, distinguishable traits; therefore, the pottery blesses

the common people to feel comfortable and relaxed using them. The secret is his

ability to infuse the purity of the earth and of tradition into his works. Thus, he employs

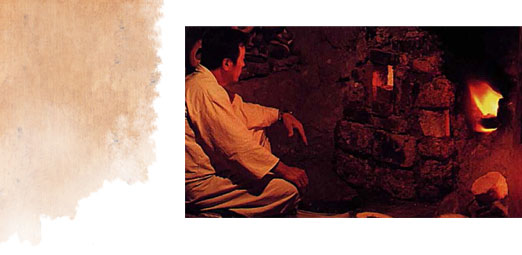

established methods and tools, for example, a mangdaengi gama, a Korean traditional

wood fired kiln that is made by building a domed tunnel with mushroom-shaped clay bricks.

This pottery kiln allows the flames to flow evenly within it, and can endure heat of more than 1,000

degrees Celsius for many years.

The use of Red- Pine to fire such a pottery kiln is another principle that has not changed for centuries and that Kim

Jeong-ok fervently follows to preserve the custom. By utilizing this special wood that produces superior flames and the

best conditions for firing, and thus adhering to unique and deep-rooted methods of tradition, he creates works of art just

as breathtaking as his ancestors.' He feels that once a piece of formed and molded clay leaves his hands, it is given

over to the mysterious forces of nature that are beyond human capacity. As one who understands the firing process

over to the mysterious forces of nature that are beyond human capacity. As one who understands the firing process

of oxidation and de-oxidation, he has no choice but to let the flames take control, to transform a lump of clay into

of oxidation and de-oxidation, he has no choice but to let the flames take control, to transform a lump of clay into

a masterpiece.

a masterpiece.

Actually, there is no scientific data to prove that Red Pine influences the quality of pottery. Like many secrets Actually, there is no scientific data to prove that Red Pine influences the quality of pottery. Like many secrets

still kept in traditional folk crafts, the firing technique is heavily dependent on the potter’s knowledge gained

still kept in traditional folk crafts, the firing technique is heavily dependent on the potter’s knowledge gained

through his experiences in his workshop. However, Red Pine does generate a stronger heat in the pottery kiln

through his experiences in his workshop. However, Red Pine does generate a stronger heat in the pottery kiln

without leaving much ash behind, which, Kim Jeong-ok believes, helps gain the brilliant white he aspires

without leaving much ash behind, which, Kim Jeong-ok believes, helps gain the brilliant white he aspires

in his ceramic works. Although a modern gas kiln is designed for the mass-production of pottery, it fails to

in his ceramic works. Although a modern gas kiln is designed for the mass-production of pottery, it fails to

generate the subtle yet significant details on the surface of the ceramics that are created by a wood fired kiln.

generate the subtle yet significant details on the surface of the ceramics that are created by a wood fired kiln.

He believes there is no basis for science in pottery-making because fire does not belong to science or mankind;

He believes there is no basis for science in pottery-making because fire does not belong to science or mankind;

it is a product of nature and of God.

it is a product of nature and of God.

Kim Jeong-ok fires his pottery kiln once every two Kim Jeong-ok fires his pottery kiln once every two

months. The first firing normally lasts about 10 hours

months. The first firing normally lasts about 10 hours

with the heat set at approximately 800 degrees Celsius, with the heat set at approximately 800 degrees Celsius,

while the second firing, which takes place after

while the second firing, which takes place after

glazing, lasts for about 12 hours with the heat kept

glazing, lasts for about 12 hours with the heat kept

as high as 1,300 degrees Celsius. Yet after the

as high as 1,300 degrees Celsius. Yet after the

firing process, only about 5% of the several hundred

firing process, only about 5% of the several hundred

pieces he has made reaches perfection. Even if

pieces he has made reaches perfection. Even if

there is only a slight fault in the color or weight,

there is only a slight fault in the color or weight,

the potter will smash the ceramic: the potter’s

the potter will smash the ceramic: the potter’s

standard of excellence is so high, a work that isn’t

standard of excellence is so high, a work that isn’t

of the best quality is simply discarded.

of the best quality is simply discarded.

|